For quality we are serious!- Cross-audit Response to Call from “Quality Month”

“Practice Full Involvement and Exceed Customer Expectation” As Shuanglin “Quality Month” is started, under the guidance of General Manager Qian Xueming, all the staffs from Shuanglin Mechanic and Electronic Devices unveiled the Quality Month on September 8th, with active responses from the division and all the factories.

For quality, we say

Chengye Factory “For quality, we are serious because it is our heart”

Transmission Factory “We vow to inject quality awareness into the blood vessels of each employee”

Punching Factory “We always put quality in our words and in our actions”

For practice, we do

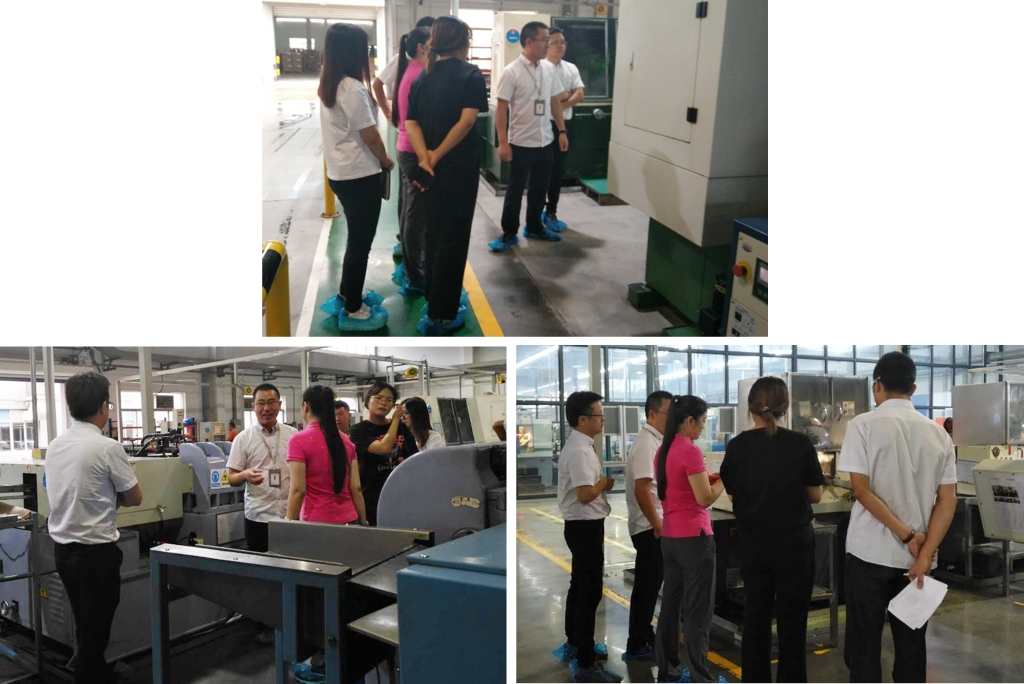

To promote the cross-learning among factories of Mechanic and Electric Devices and to build a good team atmosphere, Quality Department of Mechanic and Electric Devices performed cross-audits on its Chengye Factory, Transmission Factory and Punching Factory. The staffs organized by quality office from these three factories and Quality Department made process audits on each factory. The chiefs and management of three factories actively assisted in the activity.

September 20, Punching Factory Audit

Guided by head of quality office from Transmission Factory, members from Chengye quality office and Quality Department participated in the audit on Punching Factory. Chief and management of Punching Factory actively received them and the audit.

September 21, Transmission Factory Audit

Guided by head of Chengye quality office, members from Punching Factory quality office and Quality Department participated in the audit on Transmission Factory. Chief of Transmission Factory received them and guided the auditors to visit the entire manufacturing field.

September 22, Chengye Factory Audit

Guided by head of Quality Department, members from quality offices of Transmission Factory and Punching Factory participated in the audit on Chengye Factory. General Manager of Chengye and supervisors of its different departments showed assistance in the audit.

Through the 3-day cross audit on factories, we have found the strengths and weaknesses in terms of quality management for each factory. The result showed that our product manufacturing process is well controlled. This audit has helped quality staffs from each factory and from Quality Department to learn from one another and share quality management experience, having realized knowledge and experience sharing. They also systemically analyzed and discussed solutions to common problems.

We believe that “two heads are better than one”. With everyone’s efforts, we will definitely have quality management play an effective role in promoting operation management of the division!

Quality management system training, knowledge contest and QCC are being performed during the same period. We will share you the latest news!